Scripps Research Team Dramatically Simplifies Synthetic Production of Potential Pharmaceuticals

By Mark Schrope

A team of researchers at The Scripps Research Institute has developed new techniques that dramatically reduce the time, complexity, and cost of synthesizing natural products with pharmaceutical potential. The work dislodges previously entrenched beliefs in the organic chemistry field about how such products must be produced, and could help to advance and expand the use of natural products in drug discovery programs.

The research is being published on March 22, 2007, in the journal Nature.

Chemists are currently able to synthetically produce almost any compound, but they must typically resort to expensive, complex processes that can require dozens of individual steps. Such natural product syntheses have traditionally relied on the ubiquitous use of "protecting groups," which are extra compounds chemists use to shield reactive portions of a molecule during specific stages of a synthesis scheme. The protecting groups are eventually cleaved chemically to expose the reactive portion during later chemical reactions to complete a product's synthesis. Each protecting group used adds at least two steps to a synthesis, and the groups themselves have reactivity of their own that must be controlled to prevent adverse reactions.

"Protecting groups are almost always a direct result of an inability to address selectivity in synthesis," says project leader Phil Baran, a chemist with The Scripps Research Institute. "It is ironic that they often add an additional layer of problems on top of the preexisting ones."

Organic chemistry textbooks have long declared that the use of protecting groups was essential in natural product synthesis. "Textbooks have pointed out that avoiding protecting groups is like 'avoiding death and taxes,'" says Baran, who, along with Scripps Research Kellogg School of Science and Technology graduate students Thomas Maimone and Jeremy Richter, has now disproved the belief.

To avoid the need for protecting groups, the Baran group took an unorthodox approach. Rather than assume that reactive portions of a molecule had to be shielded during various syntheses, the researchers calculated ways to use such reactivity in an overall scheme to produce the desired final product. Baran says the reason such an approach had not been successfully developed before was likely a by-product of education. "From the beginning, we were always taught that the way to solve these types of problems is to protect functionality rather than to try to embrace it," he says.

In the Nature paper, the group showed that, without using a single protecting group, they could produce the representative members of a whole family of over 60 different marine natural products produced by the Stigonemataceae family of cyanobacteria. This family of products has a wide range of bioactivities including anticancer and antibacterial, and some may eventually be developed as commercial pharmaceutical products. The compound family was only used as an example, however, as the demonstrated concepts and principles should be applicable to the synthesis of a wide range of marine and terrestrial natural products.

"This is simply a tour de force in organic synthesis," said John Schwab, a chemist at the National Institute of General Medical Sciences (NIGMS), which supported the work. "Frequently, total synthesis is compared to mountain climbing, requiring tremendous endurance (as well as planning and finesse) over the course of dozens of chemical reactions. Baran's work represents a revolutionary change in strategy. Essentially, he's removed endurance from the equation while achieving truly practical syntheses of very complex molecules."

To synthesize the products, the Scripps Research team designed a variety of chemical reactions that maximize the bonding of carbon atoms between different molecules. In many cases, the products were synthesized in gram quantities in less than 10 steps, as compared to traditional syntheses using protecting groups that have taken as many as 30 steps to produce milligrams of product.

Use of the techniques the group has developed could therefore lead to substantially reduced production costs for natural products. This is a critical concern, as identification of a reasonably economic means of production for marine and other natural products is typically one of the most challenging hurdles in a potential drug's commercial development. An overly complex and expensive synthesis can even slow or halt the development of an otherwise promising drug candidate.

Beyond economic ramifications, Baran hopes the research will offer additional benefits to the drug discovery field. Many pharmaceutical companies' potential drug pipelines are drying up, leading some to suggest that interest in natural products should be renewed. A range of drugs from aspirin to the widely used cancer treatment Taxol has been discovered in nature, but the complexity of producing natural products has made some companies reluctant to focus on them.

"There is this far-ranging and damaging perception that natural products are too complex to be used in a drug discovery setting despite their overwhelming track record in medicine," says Baran. "I think if our work has helped in even a small way to revive the use of natural products, then we've served our purpose."

The Baran team has focused its work to date on marine natural products, because these chemical compounds from sponges, algae, and other organisms have proven a rich source of bioactivity with pharmaceutical potential, but have also been challenging to work with. Marine natural products are ideal targets for simplified synthesis techniques because they tend to be exceptionally complex, and because they are typically difficult to collect. Researchers often struggle to amass marine organism samples in quantities great enough to yield the volume of a given compound needed for research and clinical trials, much less commercial production, making better and cheaper production means all the more critical.

For the production of some products, both natural and man-made, the use of protecting groups will still be the most efficient route, says Baran. "We are not advocating that one should blindly throw away the protecting groups book just for the fun of throwing it away," he says. "It's something that should be strategically applied."

Baran, Maimone, and Richter were all authors on the study, "Total Synthesis of Marine Natural Products Without Using Protecting Groups."

This work was supported by The Scripps Research Institute, Amgen, AstraZeneca, the Beckman Foundation, Bristol-Myers Squibb, DuPont, Eli Lilly, GlaxoSmithKline, Pfizer, Roche, the Searle Scholarship Fund, the Sloan Foundation, the National Science Foundation, and the NIGMS of the National Institutes of Health.

Send comments to: mikaono[at]scripps.edu

"I think if our work has helped in even a small way to revive the use of natural products, then we've served our purpose," says Associate Professor Phil Baran (center), shown here with Nature paper co-authors Thomas Maimone (right) and Jeremy Richter.

"This is simply a tour de force in organic synthesis."

—John Schwab

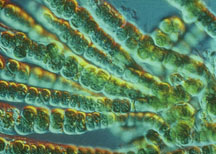

A photograph of blue-green algae cells used in the new study.